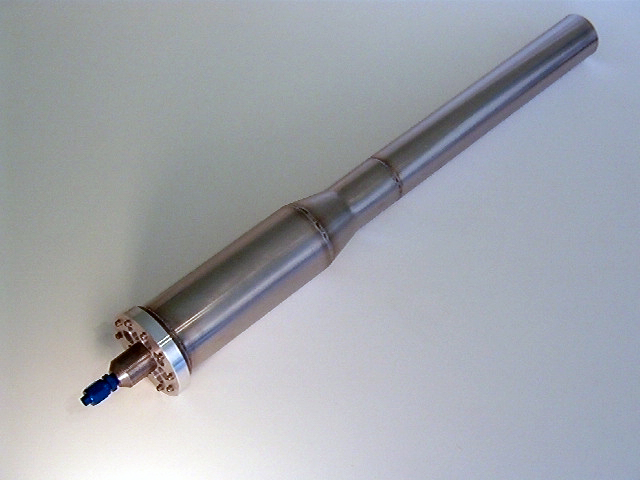

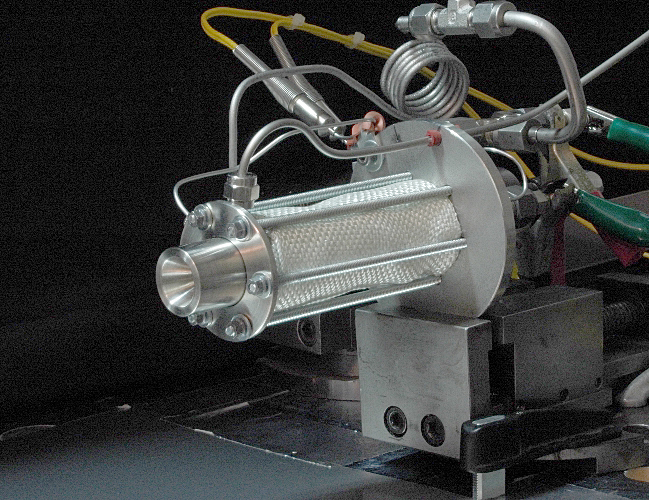

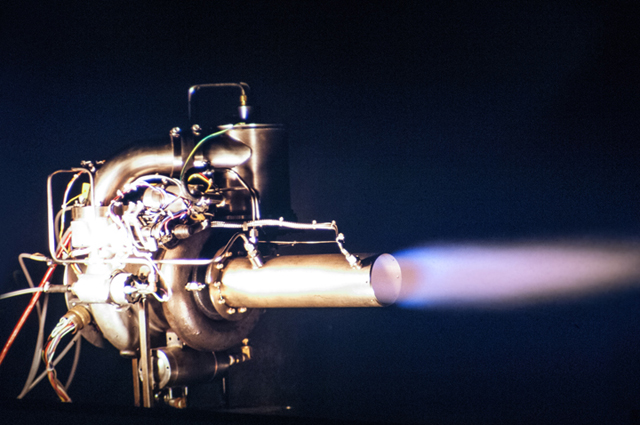

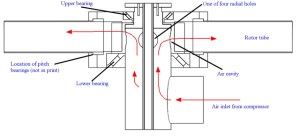

I did this design/build/test project to work in the area of rockets and thruster engines for the first time. To minimize safety risk, and to simplify the propellent system, I designed this engine to operate on moderately low-pressure gaseous oxygen and propane. The walls of the combustion chamber were cooled by integrated compressed air channels. I intentionally oversized the combustion chamber to allow for the testing of different injector plates, flame stabilizers, and combustion position sensors. Overall, it was a good learning experience, and I completed several hours of run time. The engine was well instrumented with thermocouples, pressure transducers, and infrared flame position sensors that were cooled with dry ice. The engine was started with a glo plug trigger dry chemical pyrotechnic ignitor. As part of this project, I also built a small test bunker that all of the engine tests were conducted in.