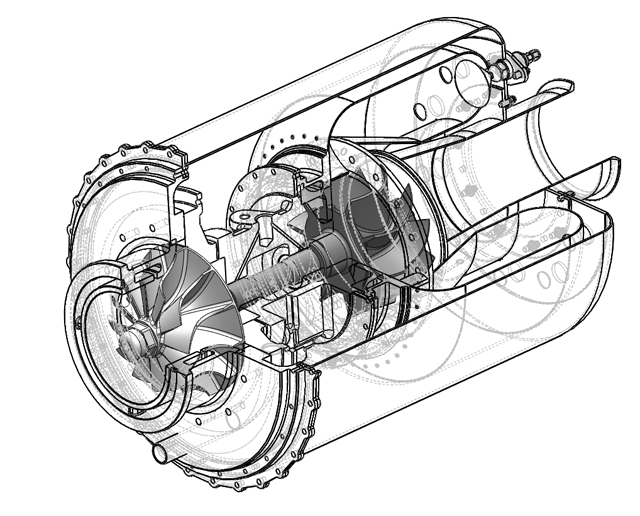

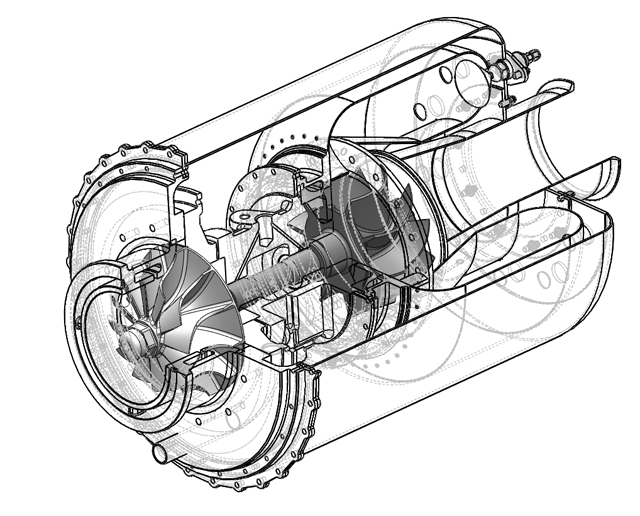

This was a whitepaper design that I did for a small general aviation turbojet in the 175 lb thrust range. I designed this engine concurrently with the Askance Asymmetric Single Seat Jet.

This was a whitepaper design that I did for a small general aviation turbojet in the 175 lb thrust range. I designed this engine concurrently with the Askance Asymmetric Single Seat Jet.

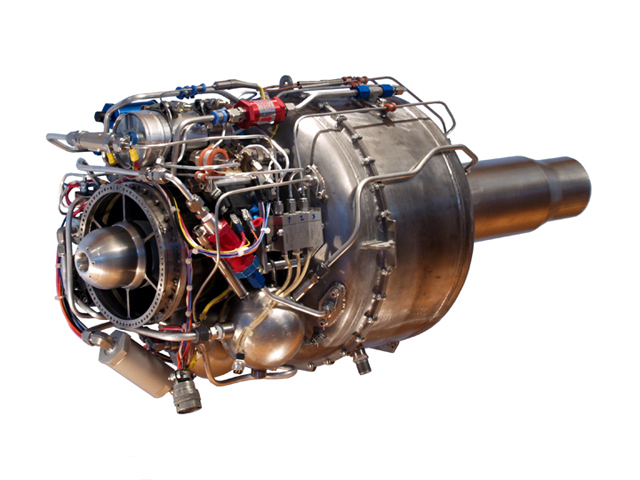

I designed, built, and tested this with the goal of evaluating the feasibility of a small general aviation turbojet. The project was a great success with several static test runs validating the engine performance and design requirement. I designed this engine concurrently with the JA103 Single Seat Jet Composite Airframe.

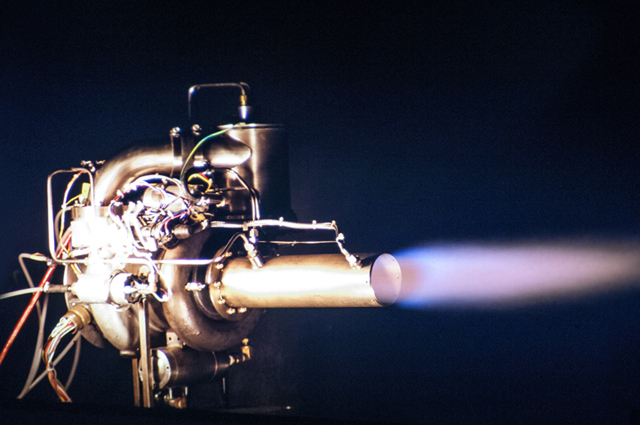

This was very successful turbojet that I built with the lessons that I learned from my previous smaller scratch-built engine design projects. I tested this engine for several total hours in multiple runs including some runs with full afterburner. I learned a lot from previously machining all of my own turbomachinery, but for this larger engine, I decided that I wanted to concentrate on engine cycle thermodynamics and engine subsystem design, so I made this engine by significantly modifying a diesel heavy equipment turbocharger. Interestingly, it was an original idea of mine to make turbocharger based jet engines at the time of this project; years later, I discovered that others were working with similar designs in Canada and the east coast around that same timeframe.

During the build of the previous kerosene centrifugal turbojet, I built 2 or 3 of each part. This engine was assembled from the second set of parts. The design intent of this engine was to improve on the kerosene centrifugal turbojet and evaluate the performance of a small ethanol can-annular chamber while experimenting with several different prototype turbine inlet nozzles. Overall engine performance was similar to the previous kerosene engine. This engine was my first can-annular engine.

This engine was a significant improvement on my first two turbojet engines. For this engine I designed and built custom compressor and turbine assemblies. The compressor wheel was sourced from a turbocharger, but I billet machined the compressor diffuser and compressor casing from scratch. The turbine was completely custom (I CNC machined it from 304 stainless steel). It was the first axial turbine assembly and annular combustion chamber that I built. The engine produced about 10 lb of thrust. The engine used a centrifugal compressor (with vaned dump diffuser), internal annular combustion chamber, axial turbine, and compressed air impingement starting. The engine was started and warmed up using propane gas. Once running, the engine was transferred to kerosene injection.

These two simple turbocharger derived turbojets were the first two successful turbine engines that I designed and built. At the time, the idea of making a turbojet from a turbocharger core was new and unique, and both engines ran relatively well. Both engines were small and produced only about 10-15 lbs of thrust.

Both engines used centrifugal compressors, single external can combustion chambers, annular inflow turbines, and compressed air impingement starting. The first engine used low pressure fuel vaporizer tubes (40 psi diesel) and a total loss lubrication system. The second engine incorporated high pressure fuel injection (kerosene) and a semi-recirculating oil system.