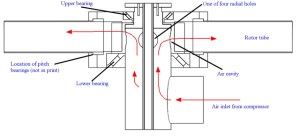

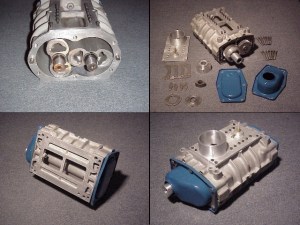

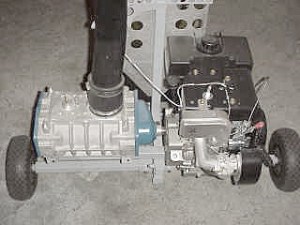

This was a small compressed air jet-tip helicopter rotor assembly and testbed that I designed and built to explore the feasibility of helicopters without tail rotors. This was the first-full sized aircraft assemly that I designed, and it was a great learning experience for mass properties management, structural analysis, and safety factors. I made the rotor blades out of fiberglass that I molded around CNC hotwired cut foam cores that were bonded to a chromoly structural tube that also functioned as the compressed air duct. A lot of the project centered around the design and fabrication of the rotor head that incorporated compressed air passages surrounding the rotor blade pitch control mechanisms. I supplied compressed air to the rotor system using a roots blower that was driven by a 4-stroke engine. I performed dozens of tethered tests running the rotor up to different speeds and variable blade pitch configurations.